Ready to Optimize Your Plant Operations? Using AI for Real-World Process Efficiency

In the manufacturing and industrial sectors, optimizing plant operations is a constant challenge. From reducing downtime to improving product quality and minimizing waste, businesses are under pressure to enhance efficiency while keeping costs in check. Enter artificial intelligence (AI)—a transformative technology that is revolutionizing how plants operate. By leveraging AI, businesses can achieve real-world process efficiency, driving productivity and profitability to new heights. This article explores how AI can optimize plant operations, its practical applications, and steps to implement it effectively.

The Need for AI in Plant Operations

Plant operations are inherently complex, involving numerous interconnected processes, machinery, and human inputs. Traditional methods of monitoring and managing these processes often rely on manual oversight and reactive decision-making, which can lead to inefficiencies, errors, and missed opportunities for improvement. AI offers a proactive, data-driven approach to address these challenges by:

Predicting and Preventing Equipment Failures: AI can analyze equipment data to predict failures before they occur, reducing unplanned downtime.

Optimizing Production Schedules: AI algorithms can optimize production timelines, ensuring resources are used efficiently.

Enhancing Quality Control: AI-powered vision systems can detect defects in real time, improving product quality.

Reducing Energy Consumption: AI can monitor and adjust energy usage, lowering operational costs and supporting sustainability goals.

Real-World Applications of AI in Plant Operations

AI is not a futuristic concept—it’s already delivering tangible results in plant operations across industries. Here are some real-world applications:

1. Predictive Maintenance

One of the most impactful uses of AI in plant operations is predictive maintenance. By analyzing data from sensors and IoT devices, AI can identify patterns that indicate potential equipment failures. This allows maintenance teams to address issues before they escalate, minimizing downtime and repair costs.

2. Process Optimization

AI can analyze vast amounts of production data to identify inefficiencies and bottlenecks. For example, AI algorithms can optimize machine settings, adjust production speeds, and recommend process improvements to maximize output and reduce waste.

3. Quality Assurance

AI-powered computer vision systems can inspect products on the production line with greater accuracy and speed than human inspectors. These systems can detect defects, measure dimensions, and ensure compliance with quality standards in real time.

4. Supply Chain and Inventory Management

AI can optimize inventory levels by predicting demand and automating reorder processes. It can also enhance supply chain visibility, enabling better coordination with suppliers and reducing lead times.

5. Energy Management

AI can monitor energy consumption across the plant and identify opportunities for savings. For instance, it can adjust HVAC systems, lighting, and machinery operations to reduce energy usage without compromising productivity.

6. Worker Safety

AI can enhance workplace safety by monitoring environmental conditions and worker behavior. For example, it can detect hazardous situations, such as gas leaks or unsafe machinery operation, and alert staff in real time.

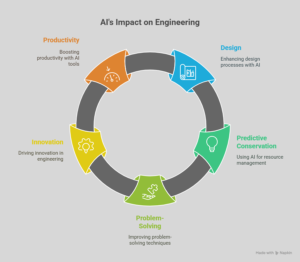

Benefits of AI-Driven Process Efficiency

Implementing AI in plant operations offers numerous benefits, including:

Increased Productivity:By automating repetitive tasks and optimizing processes, AI enables plants to produce more with the same resources

Cost Savings: Predictive maintenance, energy optimization, and waste reduction all contribute to lower operational costs.

Improved Product Quality: AI ensures consistent quality by detecting defects and deviations early in the production process.

Enhanced Decision-Making:AI provides actionable insights based on real-time data, enabling faster and more informed decisions.

Sustainability: By optimizing resource usage and reducing waste, AI helps plants operate more sustainably.

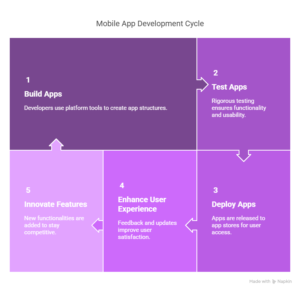

Steps to Implement AI in Plant Operations

Adopting AI for plant optimization requires careful planning and execution. Here’s a step-by-step guide to get started:

1. Assess Your Needs

Identify the specific challenges and inefficiencies in your plant operations that AI can address. This could include equipment downtime, quality issues, or energy consumption.

2. Collect and Prepare Data

AI relies on high-quality data to function effectively. Ensure your plant has the necessary sensors, IoT devices, and data infrastructure in place to collect and store relevant data.

3. Choose the Right AI Solutions

Select AI tools and platforms that align with your needs. Look for solutions that are scalable, user-friendly, and compatible with your existing systems.

4. Start with a Pilot Project

Implement AI in a specific area of your plant operations, such as predictive maintenance or quality control. Use the pilot project to test the technology and measure its impact.

5. Train Your Team

Ensure your staff understands how to use AI tools and interpret their outputs. Provide training and resources to help them adapt to the new technology.

6. Monitor and Refine

Continuously monitor the performance of your AI initiatives and gather feedback from users. Use this information to refine your approach and expand AI adoption to other areas of your plant.

7. Partner with Experts

If you lack in-house expertise, consider collaborating with AI vendors or consultants who can guide you through the implementation process.

Overcoming Challenges in AI Adoption

While AI offers significant benefits, its adoption is not without challenges. Common obstacles include:

Data Quality Issues: Inaccurate or incomplete data can undermine AI’s effectiveness. Invest in data cleaning and validation processes to ensure reliable inputs.

High Initial Costs: While AI can deliver long-term savings, the initial investment can be substantial. Look for cost-effective solutions and prioritize high-impact use cases.

Resistance to Change: Employees may be hesitant to adopt AI due to fear of job displacement or lack of understanding. Address these concerns through clear communication and training.

The Future of AI in Plant Operations

As AI technology continues to evolve, its applications in plant operations will only grow. Emerging trends such as digital twins (virtual replicas of physical assets), autonomous robotics, and advanced machine learning algorithms promise to further enhance efficiency and innovation. Plants that embrace AI today will be better positioned to thrive in the increasingly competitive and technology-driven industrial landscape.

Conclusion

AI is no longer a luxury—it’s a necessity for plants looking to optimize operations and stay ahead of the curve. By leveraging AI for predictive maintenance, process optimization, quality assurance, and more, businesses can achieve real-world process efficiency that drives productivity, reduces costs, and improves sustainability. The key to success lies in starting small, focusing on clear objectives, and continuously refining your approach. Ready to optimize your plant operations? The future of manufacturing is here, and it’s powered by AI.