IoT-Driven Predictive Maintenance: Reducing Downtime with AI-Powered Fault Detection

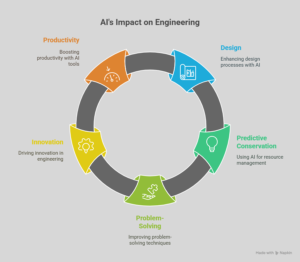

In today’s fast-paced, tech-driven industries, unexpected machine failures don’t just disrupt workflows—they cost time, money, and customer trust. That’s why more organizations are turning to IoT-powered predictive maintenance, combining real-time data collection with artificial intelligence to catch faults before they happen.

This smart approach is revolutionizing how businesses maintain equipment, reduce downtime, and improve efficiency across manufacturing, logistics, energy, and beyond.

🔧 What is Predictive Maintenance?

Predictive maintenance (PdM) is a proactive strategy that uses data analytics to predict when equipment is likely to fail. Instead of relying on scheduled maintenance (which can be too early or too late), PdM helps perform maintenance only when it’s truly needed—reducing costs and avoiding unnecessary machine downtime.

📡 Enter the Internet of Things (IoT)

IoT acts as the nervous system of predictive maintenance. Sensors embedded in machinery continuously collect data like:

- Vibration levels

- Temperature fluctuations

- Pressure and fluid flow

- Electrical currents

- Acoustic signals

This data is sent to cloud platforms where it’s stored, monitored, and analyzed—often in real-time.

🤖 How AI Supercharges Fault Detection

Once IoT devices capture the raw data, AI algorithms step in to make sense of it. Here’s how AI enhances predictive maintenance:

- Pattern Recognition: Machine learning models can detect early warning signs by comparing current data to historical patterns.

- Anomaly Detection: AI can instantly flag unusual behavior or deviations in performance—before a human operator might even notice.

- Failure Prediction: By analyzing trends and correlations, AI forecasts potential faults or breakdowns with impressive accuracy.

For example, if a motor starts vibrating slightly more than usual under specific conditions, AI can detect that pattern and trigger a maintenance alert—long before the motor actually fails.

💼 Real-World Benefits

Implementing IoT-driven predictive maintenance brings significant advantages:

- Reduced Downtime: Machines are fixed before failure, keeping operations running smoothly.

- Lower Maintenance Costs: No more unnecessary part replacements or over-maintenance.

- Extended Equipment Lifespan: Continuous monitoring prevents small issues from turning into major damage.

- Better Safety: Early detection of malfunctions reduces the risk of accidents.

- Data-Driven Decisions: Maintenance teams gain valuable insights to prioritize tasks efficiently.

🏭 Use Cases Across Industries

Manufacturing: Sensors on production lines predict equipment wear, reducing costly stops.

Energy: Wind turbines, transformers, and pipelines are monitored remotely to ensure uptime and safety.

Transportation: Aircraft and fleet vehicles are equipped with smart diagnostics to prevent mid-operation failures.

Facility Management: HVAC, elevators, and power systems in commercial buildings are monitored for continuous performance.

🚀 Getting Started: Key Components of an IoT PdM System

To implement IoT-driven predictive maintenance, you’ll typically need:

- IoT Sensors: Tailored to your equipment’s key performance indicators (KPIs).

- Connectivity: Secure data transmission via Wi-Fi, LoRaWAN, 5G, etc.

- Cloud Platform: For data storage, visualization, and integration.

- AI/ML Models: Trained to detect faults and generate predictive insights.

- User Dashboard: For real-time alerts, reports, and analytics.

🌐 The Future of Maintenance is Predictive

With advancements in edge computing, 5G, and more powerful AI models, the future of predictive maintenance looks even smarter and more scalable. Soon, machines will not only tell us when something’s wrong—but also why, how to fix it, and how to avoid it next time.

By combining IoT with AI, businesses are turning maintenance from a reactive headache into a strategic advantage.