Introduction

In the contemporary, rapidly evolving digital environment, companies consistently strive for novel methods to enhance operations, lower expenses, and improve decision-making. One of the most impactful technologies facilitating this transition is AI-driven digital twins. By developing virtual models of physical systems, processes, or products, organizations can replicate real-world situations, anticipate results, and make informed decisions with unmatched precision.

This article examines how AI-driven digital twins are transforming sectors, their primary advantages, and practical applications that promote more intelligent business practices.

What Are AI-Driven Digital Twins?

A digital twin is an active, virtual depiction of a tangible object, system, or process that employs real-time data and AI to mimic, predict, and enhance performance. When augmented by artificial intelligence (AI) and machine learning (ML), digital twins gain substantial capabilities, allowing for:

– Real-time observation – Constantly monitoring physical counterparts.

– Predictive insights – Anticipating malfunctions, inefficiencies, and possibilities.

– Automated decision-making – AI-guided modifications for optimal results.

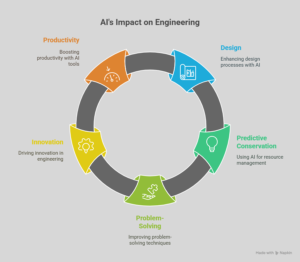

How AI Improves Digital Twins

Although conventional digital twins depend on IoT sensors and past data, AI amplifies their potential by:

1. Enhancing Accuracy – AI protocols evaluate extensive datasets to sharpen simulations.

2. Facilitating Predictive Maintenance – Identifying irregularities prior to causing downtime.

3. Streamlining Operations – AI recommends real-time enhancements for efficiency.

4. Enabling Scenario Testing – Replicating “what-if” circumstances without real-world dangers.

Key Advantages of AI-Driven Digital Twins

1. Improved Operational Efficiency

Through the simulation of production lines, supply chains, or energy systems, organizations can uncover bottlenecks and refine workflows before execution.

2. Decreased Downtime and Expenses

AI-based predictive maintenance aids in averting machinery failures, thus minimizing unexpected shutdowns and repair expenses.

3. Superior Product Development

Manufacturers utilize digital twins to assess prototypes virtually, decreasing R&D duration and costs while augmenting product quality.

4. Enhanced Supply Chain Management

By modeling logistics networks, firms can foresee disruptions, optimize pathways, and better manage inventory.

5. Enriched Customer Experiences

The retail and healthcare industries employ digital twins to tailor services, ranging from virtual fitting rooms to patient-specific treatment strategies.

Practical Applications

🔹 Manufacturing and Industry 4. 0

Entities like Siemens and GE implement digital twins to oversee factory machinery, forecast maintenance requirements, and fine-tune production timelines.

🔹 Smart Cities and Infrastructure

Municipalities utilize digital twins to replicate traffic patterns, energy usage, and emergency response situations for urban development.

🔹 Healthcare and Precision Medicine

Medical facilities generate digital twins of patients to evaluate treatment outcomes and forecast health hazards before delivering therapies.

🔹 Retail and E-Commerce

Companies such as Nike and IKEA adapt virtual models of stores to refine layouts and elevate customer interaction.

🔹 Energy and Sustainability

Utility companies replicate power grids using digital twins to balance renewable energy sources and lessen carbon footprints.

The Horizon of AI-Driven Digital Twins

As AI, IoT, and 5G progressively develop, digital twins will transform into even more advanced entities, facilitating:

– Autonomous systems (self-optimizing factories, intelligent buildings)

– Hyper-personalization (AI-driven customer interactions)

– Cross-industry collaboration (smooth data interchange among sectors)

Conclusion

AI-driven digital twins have transitioned from being a futuristic idea—they are now a competitive necessity for organizations looking to succeed in the digital era. By mimicking real-life situations, forecasting results, and streamlining decisions, businesses can realize improved efficiency, cost reductions, and innovation.

Is your organization prepared to leverage the capabilities of digital twins? The dawn of smarter operations begins today.